venturi flow meter working principle

It is invented by American Engineer Clemans Herchel and named by the Italian physicist Giovanni Venturi. The fluid whose flow rate is to be measured enters the entry section of the venturi meter with a pressure P1.

Venturi Flowmeter Flowmaxx Engineering

What is the disadvantages of venturi tube.

. A Venturi requires two pressure and one temperature measurement to accurately determine flow. Operation of venturi meter. To measure the flow rate that is discharged a pressure drop occurs between the entrance and throat of the venturi meter.

It works on the basic principle of Bernoullis Equation. Venturi PrincipleHow do venturis work. The meter works by measuring the pressure of fluid before and after it passes through a narrow tube.

Differential Pressure Flow Meter - 16 images - china differential pressure flow meter acd 3q china self actuated final control element symbol cad block rosemount 2051cfc wireless compact orifice plate flow eyc dew point chart of air conditioning dew point versus. As the velocity increases pressure decreases. Venturi Flow Meter.

A venturi creates a constriction within a pipe classically an hourglass shape that varies the flow characteristics of a fluid either liquid or gas travelling through the tube. It states that in a steady ideal flow of an incompressible fluid the total energy at any point of the fluid is constant. In the venturi meter the fluid flow rate is reduced due to the reduction of the cross-sectional area.

Any point of flowing fluid in the venturi meter there will be pressure energy potential energy and kinetic energy. The pressure difference indicates the volumetric rate of flow. As the fluid from the entry section of venturi meter flows into the converging section its pressure keeps on reducing and attains a minimum value P2 when it enters the throat.

Venturis or occasionally Venturies. This device is widely used in the water chemical pharmaceutical and oil gas industries to measure the. Cross section of throat is less than cross section of inlet pipe.

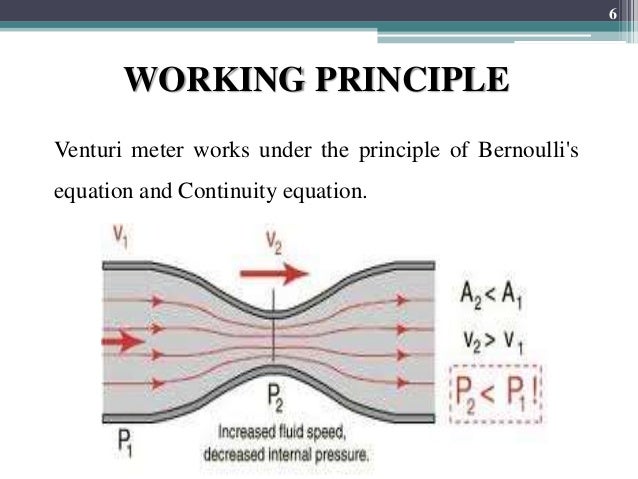

That is in the throat the fluid pressure P2 will be minimum. The restriction diameter should not be less than 0224 D and not more than 0742 D where D is the nominal bore diameter of the pipe. Venturi Meter works on the principle of Bernoullis equation.

The basic measurement principle is a flow measurement method based on the law of conservation of energy-Berlier equation and flows continuity equation. Venturimeter Working Principle. Since the cross -section decreases from inlet pipe to throat the velocity of the fluid increases and hence the pressure decreases.

Venturimeter working principle- Venturimeter is an instrument which is used to measure average velocity of a. This is used for the density calculation and the high side input to the differential pressure measurement. Let P 1 is the pressure in the inlet section P 2 is the pressure in the throat section v 1 is the velocity of the fluid passing through the inlet section v 2 is the velocity of the fluid passing through the throat section ρ is the density of the liquid and A 1 and A 2 be the area of the cross-section at inlet section.

Venturi flowmeter working principle. Venturimeter works on the principle of Bernoullis equation ie when velocity increases pressure decreases. The working of venturimeter is based on the principle of Bernoullis equation.

Venturi Meter Working Principle. Requires a long placement. As the fluid velocity in the throat is increased there is a consequential drop in pressure.

The Venturi flow meter produces a differential pressure to calculate the flow rate through a pipe. Venturi Meter is a device in which pressure energy is converted into kinetic energy and it is used for measuring the rate of flow of liquid through pipes. Install on the pipe where the flow rate needs to be measured.

Its working can be discribe into following points. The principle behind the operation of the Venturi meter or venturi tube is the Bernoulli effect as well as the Continuity equation. Venturi flowmeter is a new generation of differential pressure flow measuring instruments.

To avoid undue aerodynamic drag a Venturi tube typically has an entry cone of 30 degrees and an exit cone of 5 degrees. The Venturi meter can handle large range of flow rates of fluid than the Orifice meter but once the Venturi meter is installed the range of flow rates it can handle becomes fixed. Sees Venturi flow meter operate on the principle of introducing a flow restriction thatproduces a pressure difference between the meters upstream and downstream pressure sensing points.

The venturi meter is placed in a pipe carrying the fluid. The venturimeter works on Bernoullis principle which states that In a steady ideal flow of an incompressible fluid the total energy at any point of the fluid is constant Venturimeter consists of a converging inlet section a cylindrical throat and a diverging conical outlet section. Construction and specification of venturi meter Venturi is an example for restriction type flow meterIts work based on Bernoullis principleIn Venturi Pressure energy PE converted into Kinetic energy KE to calculate flow rate discharge in a closed pipeline.

In the convergent region as the area and pressure decreases the velocity increases and has a favourable pressure gradient ie dpdx. The simplest apparatus is a tubular setup known as a Venturi tube or simply a Venturi plural. Thus Orifice meters offer much more flexibility of operation.

The cross-section of the throat is less than the cross-section of the inlet pipe. The venturimeter works on the principle of Bernoullis equation ie the pressure decreases as the velocity increases. Disadvantages of venturi meter.

The differential pressure is related to flow and meter-specific equations have been developed to calculate inferred mass or volumetric flow. Definition Parts Working Equation Applications Installation With PDF Written by Anup Kumar Dey in Instrumentation Mechanical Pipeline Piping Design Basics Piping Interface. As the fluid from the entry section of the venturi meter flows into the converging section its pressure keeps on reducing and attains a minimum value P2 when it enters the throat.

As the cross-section from the inlet pipe to the throat decreases the velocity of the fluid increases and hence the pressure decreases. The first pressure is measured at the Venturis upstream location P1. Venturimeter is a type of flowmeter that works on the principle of Bernoullis Equation.

A venturi tube contains a throat which is smaller in a diameter to the pipeline into which it fits. Fluid flows through a length of pipe of varying diameter. The working of venturimeter is based on the Bernoullis principle.

The fluid whose flow rate is to be measured enters the entry section of the venturi meter with a pressure P1.

Venturi Principle How Do Venturis Work

Venturi Flow Meter Working Principle Animation Instrumentationtools

Facts About Orifice Flow Meters Instrumentationtools

Venturi Meter Problems Bernolli S Principle Equation Of Continuity Fluid Dynamics Youtube

Pipe Flow Measurement Venturi Flowmeters Bernoulli S Equation

Venturi Meter Construction Working Equation Application Advantages And Disadvantages Mecholic

Venturi Flow Meter Working Principle Animation Instrumentationtools

Venturi Flow Meter Working Principle Animation Instrumentationtools